| Grade |

Mooney Viscosity |

|

Packaging |

| ML(1+4) |

ML(1+4) |

Ethylene |

Diene |

Oil Content |

Form |

Wraping |

kg/unit form |

kg/Pallet |

| 125℃ |

100℃ |

Content (%) |

Content (%) |

(phr) |

| 0045 |

– |

40 |

51 |

– |

– |

Bale |

LDPE |

25 |

1,050 |

| 2060M |

40 |

– |

55 |

2.3 |

– |

Bale |

LDPE |

25 |

1,050 |

| 3045 |

– |

40 |

56 |

4.7 |

– |

Bale |

LDPE |

25 |

1,050 |

| 3070 |

47 |

– |

58 |

4.7 |

– |

Bale |

LDPE |

25 |

1,050 |

| 3092M |

61 |

– |

65 |

4.6 |

– |

Friable |

LDPE |

25 |

1,050 |

| 3110M |

78 |

– |

56 |

5.0 |

– |

Friable |

LDPE |

25 |

750 |

| X-3042E |

– |

37 |

66 |

4.7 |

120 |

Bale |

LDPE |

25 |

1,050 |

| 3062EM |

43 |

– |

65 |

4.5 |

20 |

Bale |

LDPE |

25 |

750 |

| 3072EM |

51 |

– |

64 |

5.4 |

40 |

Bale |

LDPE |

25 |

1,050 |

| 3090EM |

59 |

– |

48 |

5.2 |

10 |

Bale |

LDPE |

25 |

1,050 |

| X-4010M |

– |

8 |

54 |

7.6 |

– |

Bale |

Low melt POE |

25 |

1,050 |

| 4021 |

– |

24 |

51 |

8.1 |

– |

Bale |

LDPE |

25 |

1,050 |

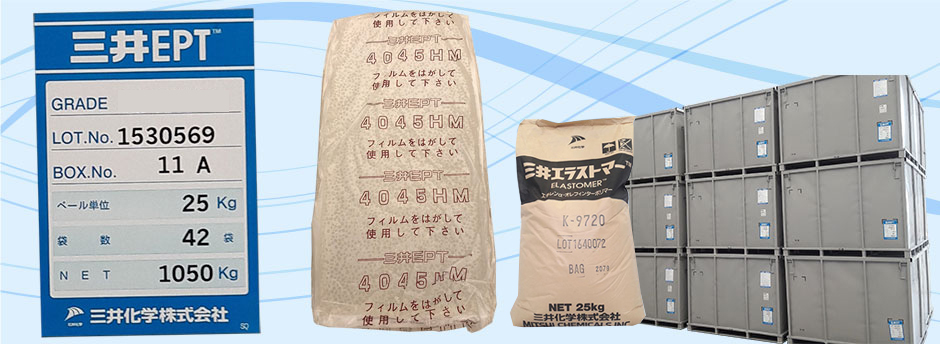

| 4045 |

– |

45 |

54 |

8.1 |

– |

Bale |

LDPE |

25 |

1,050 |

| 4045M |

– |

45 |

45 |

7.6 |

– |

Bale |

LDPE |

25 |

1,050 |

| 4070 |

47 |

– |

56 |

8.1 |

– |

Bale |

LDPE |

25 |

1,050 |

| 8030M |

– |

32 |

47 |

9.5 |

25 |

Bale |

LDPE |

25 |

900 |

| 9090M |

58 |

– |

41 |

14.0 |

25 |

Bale |

LDPE |

25 |

900 |

| 8120E |

61(150℃) |

– |

56 |

9.5 |

20 |

Friable |

LDPE |

24 |

720 |

| X-3012P |

– |

15 |

72 |

3.6 |

– |

Pellet |

Paper Bag |

25 |

750 |

| 3092PM |

61 |

– |

65 |

4.6 |

– |

Pellet |

Paper Bag |

25 |

750 |

| 3072EPM |

51 |

– |

64 |

5.4 |

40 |

Pellet |

Paper Bag |

25 |

750 |

| K-9720 |

– |

20 |

77 |

10.4 |

– |

Pellet |

Paper Bag |

25 |

750 |

| PX-049PEM |

36(150℃) |

– |

56 |

5.0 |

10 |

Friable |

LDPE |

25 |

750 |

Note :

Click “Grade Name” to more detail

All of the above listed data are representative values, and not specific ones.

EPT is a material which excels in processability, weather resistance, heat aging resistance, electrical insulation properties, cold resistance, and chemical resistance. These properties are ideal in applications such as (but not limited to) automotive weatherstrips and hoses, building materials, and electrical cables.